Business

Equipment

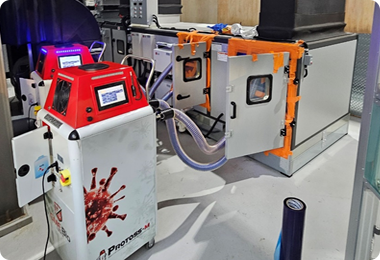

| Model | PROTOSS-M |

|---|---|

| External Material | SUS304, Al |

| Recommended Temperature | Operating: 15~30°C / Storage: 15~35°C |

| Recommended Relative Humidity | Operating: 20~85% / Storage: ~85% |

| Power Required/Consumed | AC 220 Volts 50/60 Hz, 10Amps |

| Operational Application Method | Mobile, Port, Lift Fan & Pipe |

| External Dimensions | 500 X 550 X 1254 |

| Weight | 80Kg |

| Hydrogen Peroxide Capacity | 5L |

| Hydrogen Peroxide Concentration | 30~35% |

| Operation System | Window 10 Embedded Standard |

| Data Transmission | Ethernet |

| Monitor | On board or Remote Touch Screen Monitor |

| Hydrogen Peroxide Measurement Range | 0~1,000ppm |

| Supply Gas Discharge Temperature | 60°C~70°C |

| Catalyst | Carbon+Barium |

| HEPA Filter | H14 |

| Hydrogen Peroxide Injection | 3~12g/min |

| Sterilizable Object Size | 450m³ |

| Data Storage | USB Storage |

| Wheel | Urethane (Locking Feature) |

| Electrical Safety Certification Number | R-R-GME-PROTOSS-M |

Key Features

-

Rapid Sterilization with a Maximum Injection Rate of 12g/min

: High-Capacity Injection Vaporization Technology -

Audit Trail

: Comprehensive Tracking Management of All Records -

Touch Screen Monitor+Remote Controller

-

USB Data Port

: Sterilization Process Storage Capability -

H2O2 High Level Sensor

: 0~1,000 ppm -

Cost-Effective Consumables

: Compatible with All Hydrogen Peroxide Solutions Meeting Reagent Grade Standards -

Equipped with Sensors for Enhanced Durability

: RH & TEMP Sensor -

Easy Maintenance and Cost Reduction

: Replacement of Only the Faulty Parts -

Green, Red, and Blue LED Indicators for Equipment Operating Status

-

Port Connection Method for Downtime of Production Equipment

: Vent-to-Air and Port-to-Port -

Alarm

: Audible Alarm Activated Upon Trigger -

6 Log Reduction Verification (GMP/GLP/BSL 3&4)

: Sterilization Validation Using Geobacillus stearothermophilus According to USP Guidelines -

Equipped with a 3-Directional Diffusion Fan (Front, Rear, and Side)

-

Portable System (Portable, Air-Diffusion Type) This system involves moving the PROTOSS-M and diffusion fan into the sterilization area and positioning them optimally to ensure effective sterilization, thereby eliminating microbes. -

Fixed System (Automated System) This system enables rapid sterilization using an integrated lift fan and nozzle installed on the ceiling of the sterilization area. By not bringing the PROTOSS-M and fan into the room, it minimizes the risk of contamination from external sources. -

HVAC System (Air Handling Unit) This system connects the PROTOSS-M to the air handling unit port, allowing for the sterilization of the HEPA Box interior before replacing the HEPA filter.

GLP Lab Cases

GMP Sterile Production Facility Cases

BSL3 Facility Cases

PVHP Automated System Cases

HEPA Box Cases

HVAC Cases