Business

Equipment

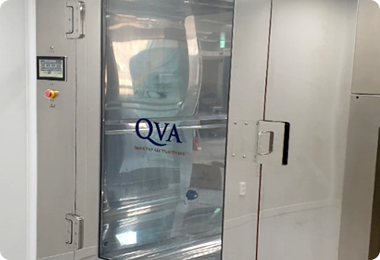

| Model | QVA |

|---|---|

| External Material | SUS304 |

| Recommended Temperature | Operating: 15~30°C / Storage: 15~35°C |

| Recommended Relative Humidity | Operating: 20~85% / Storage: ~85% |

| Power Required/Consumed | AC 220 Volts 50/60Hz, 10 Amps |

| Internal Chamber Dimensions |

Pass Box : 700(W)x1,400(D)x800(H) Pass Through : 1,000(W)x1,700(D)x1,500(H) 1,000(W)x1,600(D)x1,700(H) 1,320(W)x2,100(D)x2,230(H) *Customizing Available(Optional) |

| External Dimensions |

Pass Box : 1,400(W)x1,500(D)x2,000(H) Pass Through : 1,500(W)x1,800(D)x2,150(H) 1,500(W)x1,800(D)x2,000(H) 2,000(W)x2,200(D)x2,450(H) *Customizing Available(Optional) |

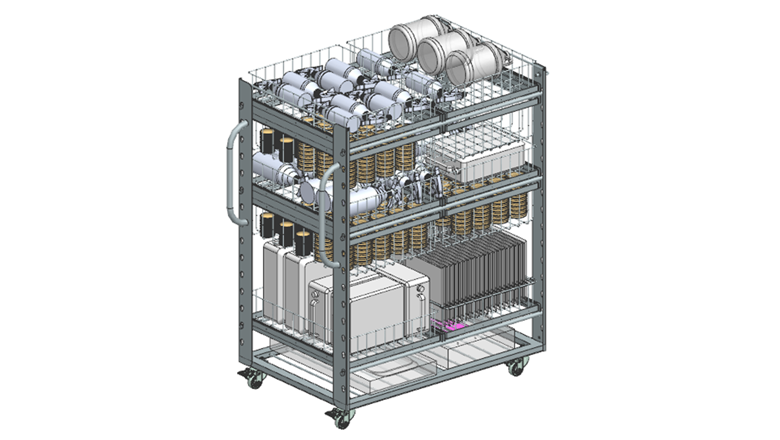

| Loading/Transporting Shelf and Cart Size |

*Customizing (Optional/Made-to-Order Based on Items) *3D Design Drawing Service |

| Hydrogen Peroxide Capacity | 1L/5L |

| Hydrogen Peroxide Concentration | 30~35% |

| Operation System | Window 10 Embedded Standard |

| Monitor | Loading & Unloading Touch Screen Monitor |

| Chamber Lamp | RGB LED Lamp |

| Data Transmission | RS485 |

| Hydrogen Peroxide Measurement Range |

0-1,000 ppm (Standard Installation)

0-10 ppm (Optional) |

| Chamber Pressure Sensor | -2,000kPa~+2,000kPa |

| Electronic Scale | 6kg |

| Ambient Temperature and Humidity Measurement Range | Temperature: -40°C to 60°C / Humidity: 0% to 100% |

| Supply Gas Discharge Temperature | 40℃~70℃ |

| HVAC Supply HEPA Filter | 99.997% |

| Hydrogen Peroxide Injection | 4g/min, 12g/min |

| Data Storage and Output | USB Storage and Printer Output |

At GME Bio, we assign specialized engineers from the outset of the QVA(Pass Box & Pass Through) project.

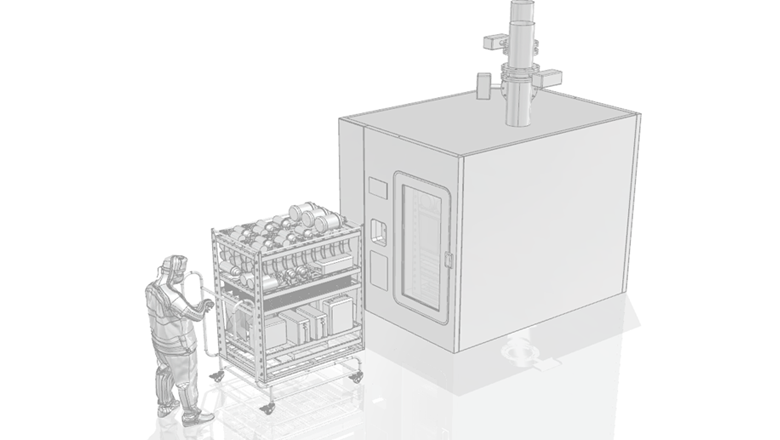

We provide clients with optimal solutions tailored to their loading patterns and deliver high-quality 3D visualization services.

This ensures reliable sterilization outcomes without failure.

GME Bio is committed to offering superior products and services in space sterilization.

Key features

-

Automatic Air-Tight Door System

: Gasket Built into the Door Gaps Automatically Expands to Ensure a Perfect Seal Between the Chamber’s Interior and Exterior -

Green, Red, and Blue LED Indicators for Equipment Operating Status

-

Touch Screen Monitor

: Bidirectional (Loading/Unloading) Monitoring Capability -

Alarm

: Audible Alarm Activated Upon Trigger -

Distribution Fan

: Diffusion Fan to Increase Sterilization Efficiency -

HVAC By-Pass Auto Valve

: Prevents Contamination Due to Differential Pressure Changes During Sterilization -

H2O2 High Level Sensor

: 0~1,000 ppm -

Electronic Scale

: Enables Quantitative Hydrogen Peroxide Injection and Real-Time Remaining Amount Monitoring -

Equipped with Sensors for Enhanced Durability

: RH & TEMP Sensor -

Buzzer & EMS Switch

: Bidirectional(Loading & Unloading) -

Adequate Hydrogen Peroxide Solution

: 1L / 5L -

Inkjet Printer

: Real-Time Output of Sterilization Process Results -

H14 HEPA Filter

: Filters 99.997% of Particles as Small as 0.3µm -

USB Data Port

: Sterilization Process Storage Capability -

Audit Trail

: Comprehensive Tracking Management of All Records

Additional Options

-

H2O2 Low Level Sensor 0.0-10.0 ppm

: Measures Hydrogen Peroxide Concentration in 0.1 ppm Increments -

H2O2 Portable Sensor

: Detects Hydrogen Peroxide Leaks Outside the Sterilization Area -

Cart to Tray System

: Designed for Effective Sterilization -

Exhaust Catalyst Unit Box

: Catalytic System for Decomposing Hydrogen Peroxide Vapor -

Pressure Decay Test

: Leak Testing Function for Chamber Interior -

Door Inter Phone

: Facilitates Communication Between Internal and External Operators

PVHP Pass Box – GMP Facility

PVHP Pass Through – GMP Facility

PVHP Pass Through (Deconlock) – BSL3, ABSL3 Facilities