Business

GMP/GLP/BSL3 Cleaning

Process Flow

Certified cleaning technicians use certified cleaning supplies and follow the established procedure.

-

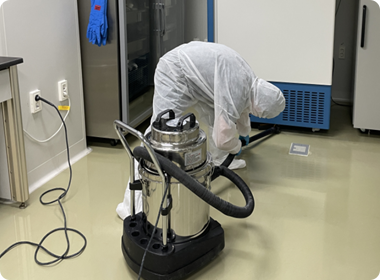

Dust Collection Work

With a HEPA vacuum cleaner appropriate for the grade

-

1st Cleaning

1st cleaning using ethanol disinfectant: ceiling, walls, fixtures, and floor in sequence

-

2nd Cleaning

2nd cleaning using endospore disinfectant:

Hydrogen peroxide 6%, chlorine-based, 4th-grade ammonium, etc -

3rd Cleaning

Surface rinsing process:

Using sterile distilled water

'Cleanliness' is a crucial aspect in facilities involved in the manufacturing, processing, packaging, and storage of pharmaceuticals. If raw materials or intermediate products are not properly managed due to contamination in the workplace, it can impact the quality of pharmaceuticals. Therefore, it is recommended to establish a quality assurance system related to cleaning in facilities such as GMP facilities, hospitals, and HACCP facilities, and to maintain a clean environment that complies with it.

GME Bio's cleaning team, consisting of GMP/GLP/BSL3 cleaning specialists, quickly assesses the site and performs cleaning based on the Know-How accumulated over time. The products used in this process are from Texwipe, the American company that developed the world's first cleanroom consumables 50 years ago; Contec, a global leader in cleanroom and hygiene management solutions; and Merck, known for its high-quality pharmaceutical products and research solutions.

GME Bio's cleaning team, consisting of GMP/GLP/BSL3 cleaning specialists, quickly assesses the site and performs cleaning based on the Know-How accumulated over time. The products used in this process are from Texwipe, the American company that developed the world's first cleanroom consumables 50 years ago; Contec, a global leader in cleanroom and hygiene management solutions; and Merck, known for its high-quality pharmaceutical products and research solutions.